![]()

Today (8/21/00) I decided, if I was going to put this much time, and effort into a steering box, I might as well build a "test" stand similar, to that pictured in the Bentley "official service manual". This way I could check play, precisely, and make sure that this box conforms with all the specs. I can also adjust it more precisely on the stand.

![]()

This is a pic, from the Bentley "official service manual" of what the steering box "adjuster-stand" is supposed to look like.

![]()

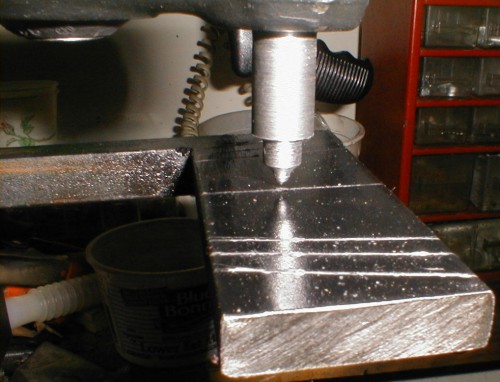

So I grabbed some metal stock, I had lying around, and with a little bit of drilling, some measuring, some welding, some machining, a protractor, and a little luck, I came up with this.

![]()

The only hard part, was machining the pointer... The pointer had to have a specific taper, so it would fit correctly, and give an accurate reading. After a few tries, I came out with one that's perfect

![]()

I also had to machine a "centering-screw"... Its basically a metric screw that will thread into the pitman arm; but it needs to have a point, so that when you line everything up to center, you can make an impression on the flange of the steering box (for reference purpose; and it also holds everything centered for installation).

![]()

Here's a top view, after everything was assembled. You can see, 3 scratchmarks on each side of that piece of metal... The middle one on each side, is 11�, and each of the inner, and outer marks are 2�. The theory behind this, is that you put the pointer on 11�, and hold the steering shaft, while you move the pitman arm back and forth, and see if it exceeds +/- 2�. Mine did not, BUT it did have more play on one side, compared to the other, which means it needs to have a thinner adjusting shim installed. So I will do that later, and re-check it.

![]()

Here you can see the pointer, and the marks.

![]()

I have tons of stuff I have to get done on the 22nd, so I may not get to the steering box. (though, I may have enough time to do something small.) So, I will get back to it, on the 23rd. I need to take it apart again, install a thinner shim, check it again. If it checks out O.K. Then I will install the oil seals, fill it with oil (check for leaks), and put it back in the car.

Stay tuned for PART 8!!!!

![]()